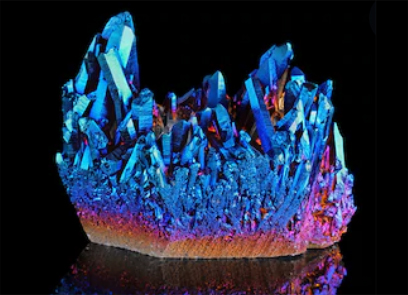

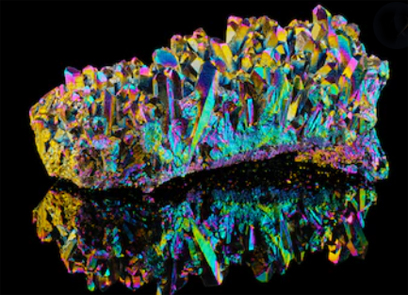

PVD coatings are generally produced in 1-5 micron layer thicknesses. The coatings are carefully matched to the upper surface end of the base material. The surface roughness of the substrate almost does not change after the coating process. After coating, the sharp edges and surfaces of the tool remain sharp as in the uncoated state.

PVD coatings constitute the finishing step in coating building elements, decorative products and tools. Despite high hardness, PVD coatings are not brittle and show high adhesion values. Layers do not form any cracks or crevices under high loads.

The advantages of the PVD coating process are as follows;

Coating composition varies over a wide range,

The process allows not only stable materials to be used as coating materials, but also semi-stable materials to be used in coating.

Deposition speed is high,

There is good adhesion between layer and substrate,

The process allows layer coating on any kind of substrate,

The system does not pose a problem in terms of human health and environmental pollution.

NOTE: When the physical structure of the products to be coated and the required surface quality are established, the coating life can be extended up to 10 years.

PVD coatings constitute the finishing step in coating building elements, decorative products and tools. Despite high hardness, PVD coatings are not brittle and show high adhesion values. Layers do not form any cracks or crevices under high loads.

The advantages of the PVD coating process are as follows;

Coating composition varies over a wide range,

The process allows not only stable materials to be used as coating materials, but also semi-stable materials to be used in coating.

Deposition speed is high,

There is good adhesion between layer and substrate,

The process allows layer coating on any kind of substrate,

The system does not pose a problem in terms of human health and environmental pollution.

NOTE: When the physical structure of the products to be coated and the required surface quality are established, the coating life can be extended up to 10 years.

+90 212 485 94 45

Stay on Follow